Project Background

Construction Task: Installing 300mm Diameter Round Piles

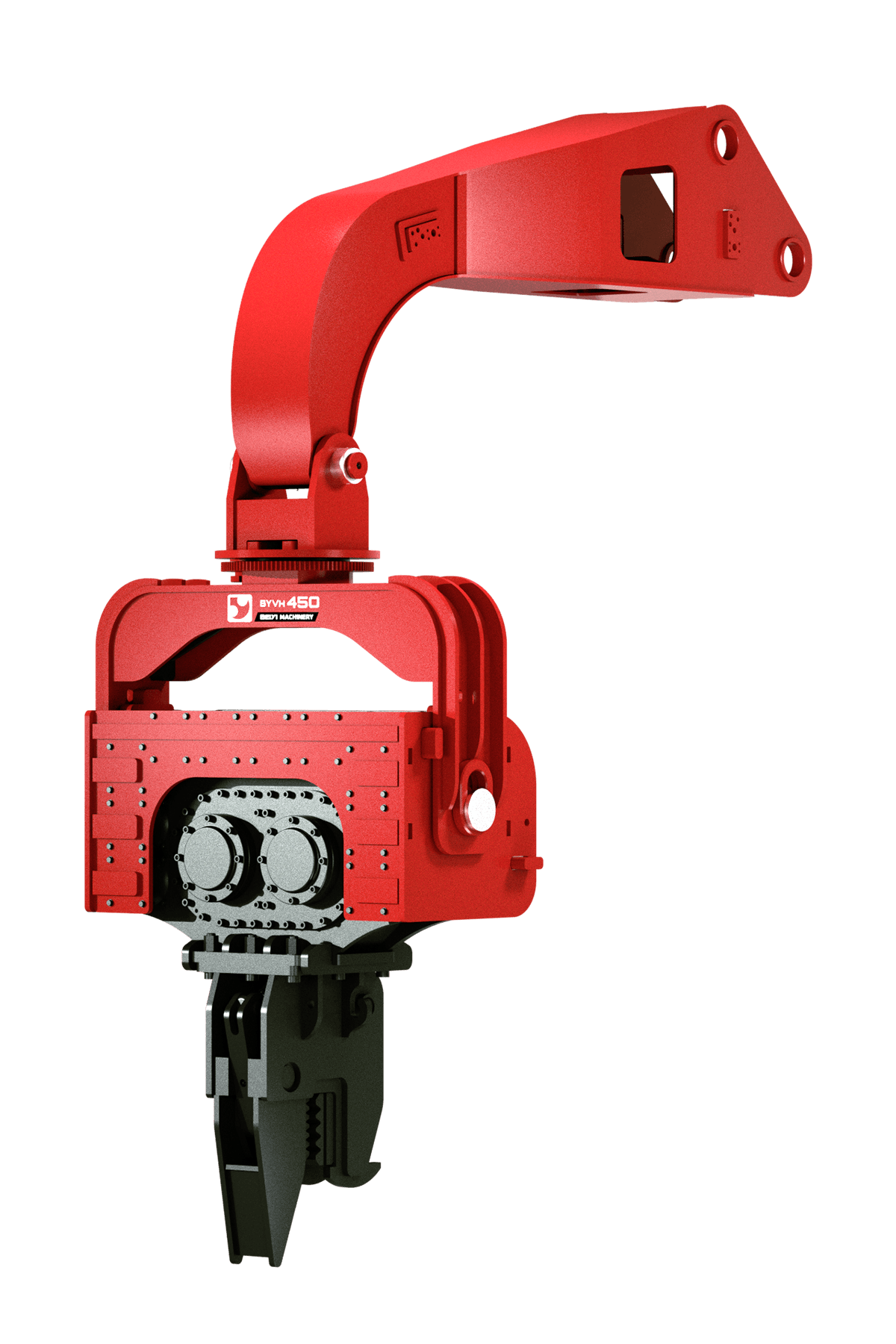

A construction site in Changzhou faced a complex task: completing a large volume of 300mm diameter round pile installations within a short timeframe. The site was equipped with a modern 215 excavator and a Caterpillar 323 excavator, and the client required two 250-type vibro pile drivers. Due to a limited budget and tight schedule, the client faced several challenges in equipment procurement.

Client’s Needs and Challenges

Client Needs: Low-cost, high-quality completion of the project

1. Cost Control: The client wanted to reduce costs and considered borrowing a second-hand pile driver from a friend, planning to purchase an earth drill first.

2. Project Schedule: With a tight project timeline, any equipment failure or delay could result in project setbacks.

3. Equipment Compatibility: The site’s soil conditions were complex, and the client needed equipment that could operate efficiently in such conditions.

4. After-sales Service: The client was looking for comprehensive after-sales support, including equipment installation, commissioning, and ongoing service.

Solution and Implementation Process

Understanding the Client’s Needs and Providing Professional Advice from Their Perspective

1. Online Installation Guidance to Save Costs:

Due to soil conditions, the client decided to purchase an earth drill first. To save on installation costs, we provided online guidance for the drill setup. This not only solved installation challenges but also saved costs for the client.

2. Second-hand Equipment Risk Advisory:

To meet the tight schedule and reduce costs, the client was considering using a second-hand pile driver from a friend. Our experts informed the client about the potential risks of second-hand equipment, such as high failure rates, costly repairs, and difficulty in finding compatible spare parts. These issues could significantly impact project progress and cost control.

3. On-site Inspection for Peace of Mind:

After weighing the potential risks of second-hand equipment, the client decided to purchase new equipment. We invited the client to visit our factory and conduct an on-site inspection of our production equipment and processes. The client was impressed by the quality of our products and our technical capabilities.

After-Sales Service and Feedback

After-Sales Service: Always Ready to Assist the Client

1. Equipment Installation:

Once the client’s pile drivers arrived, we sent a team of professional technicians to the construction site to assist with the installation and commissioning of the equipment.

2. Ongoing Support:

During the operation of the equipment, we conducted regular follow-up visits to assess the equipment’s performance, providing timely technical support and maintenance as needed. The client expressed high satisfaction with our response times and technical support.

3. Client Feedback:

Upon completion of the project, the client gave us positive feedback on both the product and our services. They highly praised our equipment performance, customer service, and problem-solving abilities.

Conclusion

By providing genuine, thoughtful service from the initial equipment purchase to the advisory on second-hand equipment risks, followed by a factory visit and smooth order placement, we earned the client’s full trust. The sincerity with which we serve our clients helped build a strong, lasting relationship.

In the future, we will continue to focus on the client, constantly improving our technical capabilities and service quality, and providing high-quality products and services to more clients.

sales@wxbychina.com

sales@wxbychina.com

Vibratory Pile Driver

Vibratory Pile Driver

HOME

HOME ABOUT

ABOUT PRODUCTS

PRODUCTS CASES

CASES VIDEOS

VIDEOS