Ordering 14 Vibro Hammers at Once

Reliable Delivery for an Indonesian Construction Project

In a green energy infrastructure project in Indonesia, the contractor decided to deploy 14 vibro hammers in a single batch for large-scale steel sheet pile installation.

This decision was not made impulsively.

It was the result of a rational evaluation based on site conditions, schedule pressure, and long-term project experience.

Project Background & Construction Challenges

During the equipment selection stage, the construction team focused on several fundamental but critical questions:

Can the equipment operate continuously and reliably under a large pile volume and long construction cycle?

In aligned steel sheet pile installation, can pile position and verticality be easily controlled?

Is the construction process predictable, allowing the overall project schedule to remain on track?

For foundation works of this scale, once the equipment type is selected, there is almost no room for adjustment.

If the equipment proves unstable, every downstream process is forced to absorb high error correction costs—leading to delays, rework, and budget overruns.

The project required one clear outcome:

stable efficiency with fully controllable results.

Why Vibro Hammers Were Chosen

After evaluating multiple solutions, the vibro hammer emerged as the most reliable option, offering the best balance between efficiency, stability, and construction control.

1. More Controllable Penetration, Greater Installation Stability

Unlike traditional impact piling, vibro hammers use high-frequency vibration to reduce soil friction.

Steel sheet piles penetrate the ground smoothly under vibration and self-weight.

For the contractor, this translated into:

Precise pile positioning

Improved verticality control

Minimal adjustment and rework

In large-scale, continuous sheet pile installation, stability itself becomes efficiency.

2. Predictable Environmental Impact, Lower Project Risk

Experienced construction teams understand a key reality:

The real uncertainty lies not in vibration, but in impact.

Vibro hammers apply force in a continuous and uniform manner, making their influence on surrounding structures clearer and easier to assess.

This predictable behavior is especially valuable for projects:

Near existing facilities

With strict environmental or regulatory requirements

As a result, vibro hammer solutions are often easier to pass construction management and environmental reviews.

3. Continuous Operation Ensures a Controlled Construction Rhythm

This project involved long-term, large-scale execution, not short or isolated tasks.

In such conditions, equipment stability directly determines whether progress remains controllable.

Vibro hammers demonstrated clear advantages:

No reliance on repeated heavy impacts

Stable operating rhythm

Well-suited for long working hours and multi-shift operations

For project managers, consistent daily progress is far more valuable than peak single-cycle performance.

“Fourteen Stable Metronomes on Site”

The site manager commented:

“With such a tight schedule, the performance of these 14 machines exceeded our expectations.

They worked like 14 stable metronomes, keeping the entire project fully under control.”

Why Order 14 Units at Once?

The decision to introduce 14 vibro hammers in one batch reflects a high level of trust.

At this project scale, the client was not selecting a single machine, but a replicable and sustainable construction solution.

Ordering 14 units meant:

The construction method had been fully validated

Equipment stability could withstand large-scale deployment

Delivery and service capabilities were proven reliable

At this level of execution, there is no room for trial and error.

More Than Equipment — A Predictable Construction Capability

Backed by extensive experience in overseas infrastructure projects, BEIYI integrates predictability and reliability into every stage, from design and manufacturing to delivery and after-sales support.

What we deliver is not just individual machines,

but a construction capability that can be planned, scaled, and trusted.

sales@wxbychina.com

sales@wxbychina.com

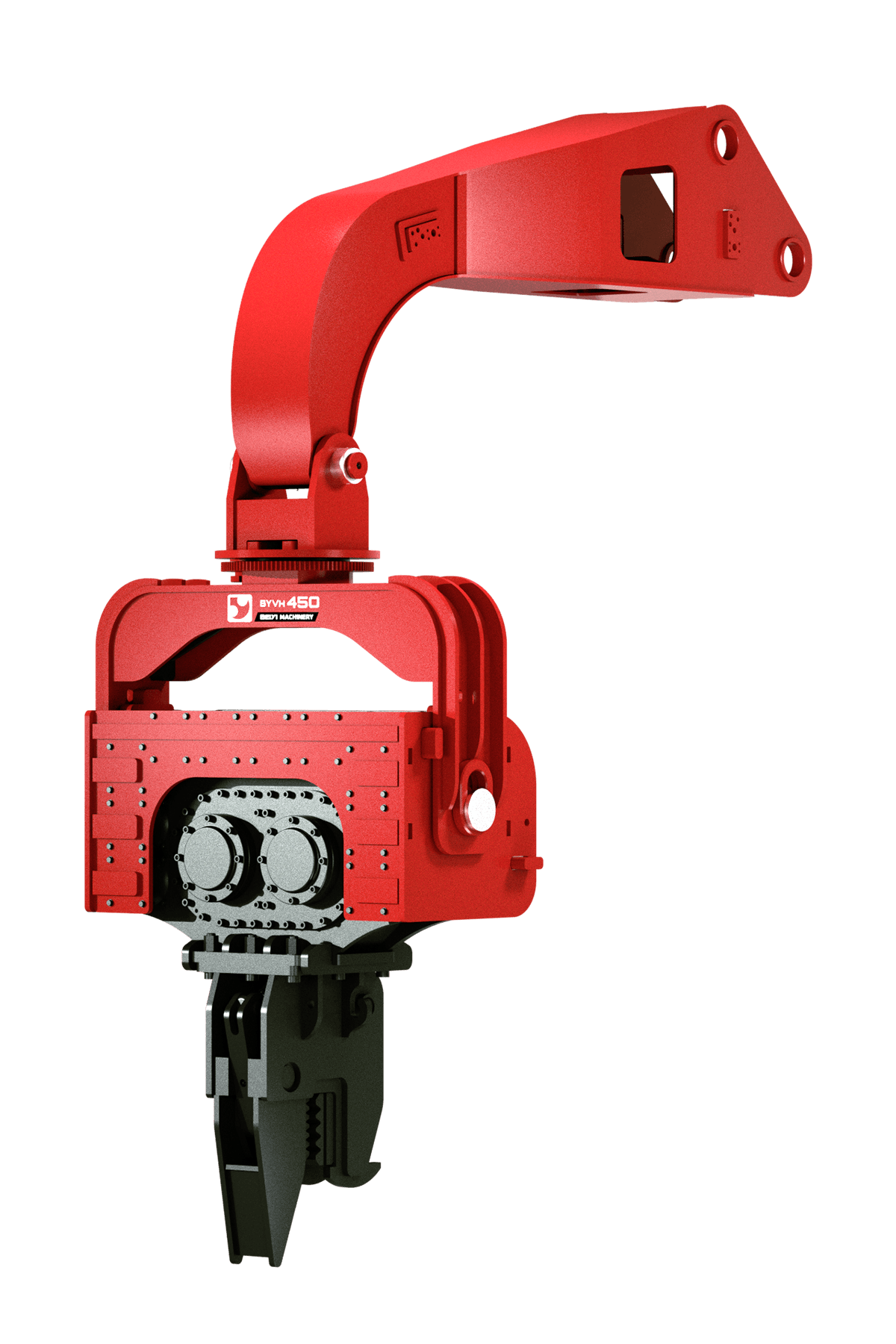

Vibratory Pile Driver

Vibratory Pile Driver

HOME

HOME ABOUT

ABOUT PRODUCTS

PRODUCTS CASES

CASES VIDEOS

VIDEOS